See A House Built Using Thin Joint Blockwork

A Better build in half the time

Recommended thin joint contractors

Leading Thin Joint Blockwork Specialists

Tenders for New Builds

Welcome & Returned Quickly

Thin Joint Blockwork & Brickwork Services

Contract Services include:

- Supply & Fix Complete Superstructure

- Supply & Fix Masonry Walls

- Labour Supply & Sundries

- Labour Supply

Experienced Qualified Staff:

- NVQ Qualified Bricklayers

- Approved Thin Joint Specialists

- CSCS Trained Workforce

- CPCS & NPORS Trained Telehandler Operatives

Sectors for Thin Joint:

- Commercial & Industrial

- New Housing & Self Builds

- Health care & Education

- Domestic Extensions

Thin Joint Blockwork aka Ra Build – Why do people want to use it?

Costs

Calfordseaden an independent construction consultants were asked to carry out an overall cost comparison when constructing 20 new 3 bedroom houses of the exact same size, layout and specification, all were required to meet the same U-value built to a code level 3 for sustainable homes standard. The research was to discover the true cost over the five most popular construction methods available:

Calfordseaden an independent construction consultants were asked to carry out an overall cost comparison when constructing 20 new 3 bedroom houses of the exact same size, layout and specification, all were required to meet the same U-value built to a code level 3 for sustainable homes standard. The research was to discover the true cost over the five most popular construction methods available:

- Thin joint blockwork / Ra Build

- SIPs

- Timber frame

- Aggregate masonry blocks

- Aircrete masonry blocks

The overall cost comparison takes into account the varying labour, plant and material costs over these five different ways to build.

Prices for labour, materials and plant were established using a selection of market rates, approved contractors and actual prices returned from contractors and suppliers including regional variations.

You can see the table below to discover their findings:

Results Overview

Thin Joint vs Timber Frame Thin Joint vs SIPS Thin Joint vs Aggregate Thin Joint vs Aircrete8.2% Cost Saving 8.2% Cost Saving 2.1% Cost Saving 1.9% Cost Saving

Cashflow & Risk

Less Financial Risk

SIPS and Timber Frame houses require a contract to be placed with a manufacturer some months before delivery. This also requires a hefty deposit to be paid, with many asking for 90% of the costs upfront. Any company holding a hefty deposit for many months is a risk, if they were to go into administration during that time, you’ll lose your deposit and possibly the dream of building your new home.

Thin Joint and Traditional Masonry also require a contract in place to begin construction, however often times no deposit is required by the contractor. Most masonry contractors work on a stage payment agreement, which allows finances to move from your account once work has been completed at the agreed stages.

The risks are lower because if the contracted company were to go into administration you’ve already had the work carried out and materials delivered to site with any outstanding materials yet to be paid for. Time finding another contractor would be your loss in this instance.

Speed of Construction

Reduces Build Times

When building methods refer to the speed of construction, they refer to a watertight superstructure (the inner leaf of the building) The roof would need to be felt and battened and the windows installed. Once in place additional trades can begin work inside the property thus reducing the overall time of the build.

As a result no comparison for a watertight inner leaf superstructure can be made for traditional block masonry (aircrete and aggregate). Because a traditional buildings inner and outer leaf walls are constructed in brickwork and blockwork simultaneously – a different build process.

This speed comparison is based on an average sized 3 bedroom semi-detached house in the UK between Timber frame, SIPS and Thin Joint Masonry.

Timber frame and SIPS – take 7-10 days to erect a watertight superstructure on-site, with the external brickwork still to be constructed.

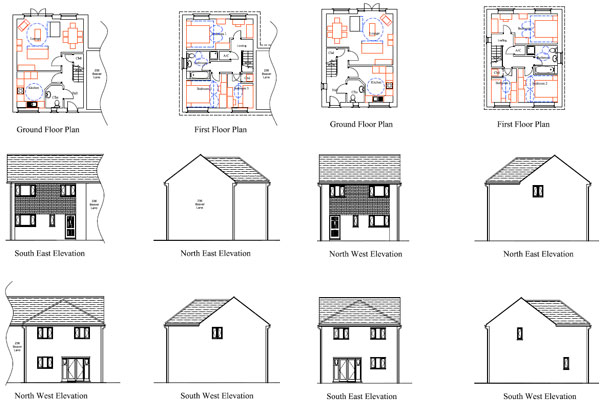

Thin Joint Blockwork – takes 5-7 days to erect a watertight superstructure on-site. In our own business we have constructed a pair of 3 bedroom houses with both inner and outer leaf walls constructed using thin joint blockwork, including the timber joist floor construction of both first floors in just 10 working days ready for roof. The two houses were watertight (roof and windows installed) within 14 days.

“Two houses built in 10-days using thin joint blockwork”

These particular properties were built in 10 days by 1 bricklayer, 1 labourer and 1 carpenter. External walls were later finished using a synthetic waterproof coloured render.

Comparing build methods in this instance Thin Joint is actually faster then Timber Frame and SIPS because the entire inner and outer leaf walls were constructed. However we have found projects which have an external brickwork finish show a ‘matched speed’ in overall construction times across timber frame, SIPs and thin joint.

Comparing the Speed of Traditional Blockwork and Thin Joint Blockwork

We can compare the laying speed of thin joint vs traditional sand and cement laid blockwork. In our own business when laying blocks with sand and cement mortar we expect our bricklayers to lay between 150 – 200 blocks a day each; which equates to 15-20m2 of production per bricklayer.

Building with Thin Joint blockwork, using larger formatted blocks, the speed of workability and faster drying times, each one of our bricklayers are averaging 40-45m2 a day – 3 times more production, in our experience it’s 63% faster.

This increase in speed means we can complete work faster, work in smaller teams of bricklayers keeping quality control high and be an advocate of training future bricklayers for our industry.

There are three fundamentals to bricklaying – plumb, gauge and level. The thin joint system eliminates two of those ‘gauge and level are not required’ because of this – we can train local apprentice bricklayers to use thin joint blockwork to a commercial standard much quicker then any other masonry build method.

Build Quality

The quality of a thin joint build is greatly increased by a number of factors, including better air tightness, sound reduction, reduced heat loss, reduced cold bridging, solid robust walls, increased bond strength, cleaner cavity walls, reduced wall tie defects, improved accuracy of wall construction and excellent resistance to fire.

Quieter, warmer, more energy efficient building

Reduced Air loss, Sound Transference & Heat Loss:

The chemical reaction that forms the thin joint blocks structure, results in each block being

made up of millions of non-interconnecting cells. This structure is key to many of the products benefits, as it prevents the passage of heat, sound and moisture through the product.

“Thin Joint achieves energy ratings of ‘A+’ and can be used in passive house construction”

The Green Guide To Housing

This is further enhanced by the use of thin joint mortar, which reduces the thickness of the mortar joints from 10mm to 2mm and ensures the joints are fully-filled, reducing the passage of anything from one side of the wall to the other – resulting in a quieter, warmer, more energy efficient home.

Stronger Walls

Solid robust walls with increased bond strength:

Thin joint walls are solid and robust using blocks with compressive strengths of 2.80, 3.60, 7.30 and 10.30 N/mm2. Walls can take the pressures of heavy RSJ’s/steel work, heavy concrete beam & block floors and pre-cast concrete floor planks with ease.

Thin joint mortar increases bond strength, the mortar used is mixed to a tile adhesive consistency which sets in 15 minutes once applied to the block and reaches full strength within 2 hours.

Thermalite and aircrete blocks when used with sand and cement mortar will instantly suck the water/moisture leaving the mortar to dry too quickly. This reduces the mortars bond strength and affects stability of walls until loads are placed on top of walls adding downward pressure strength. Also the setting time is 24 hours, much longer then thin joint which restricts the height you can build in one day.

Straighter, flatter, smoother walls

Improved accuracy of wall construction:

Thin joint blocks are manufactured to 1mm +/- accuracy, larger format blocks make keeping walls true and upright an easier task, whilst the quick setting mortar used quickly stabilises the wall. This also means there is no height build restrictions when using the thin joint system.

Compare this to sand and cement mortar and us bricklayers refer to the term ‘swimming’ because the reduced bond strength and longer drying times of traditional sand and cement mortar, results in blocks moving to inaccurate levels if we build walls too high in one day.

Straighter, flatter, smoother walls won’t only give you a nice interior finish, it will also make work for follow on trades – plasterers, electricians, carpenters and window fitters, easier and quicker, which ultimately helps speed up the project.

Reduced Future Structural Defects

Cleaner cavity walls and better installation of wall ties:

Thin joint uses 75% less mortar then a traditional build, mortar overspill is quickly cleaned off, which leaves an immaculate clean cavity wall.

When thin joint block work is used for both external and internal walls ‘normally with a render finish’. The wall ties are drilled through both internal and external leafs securely tying the walls together, this is done after the walls are built which gives a clean wall tie, eliminating the common problem of mortar build-up on wall ties which can later cause damp problems.

When thin joint blockwork is used with a brickwork outer leaf, the wall ties are driven cleanly through the insulation and fixed into the inner leaf blockwork whilst constructing the brickwork, free from mortar build up.

Better Fire Resistance Then Timber Frame & SIPS

Standard blocks non bearing walls (100mm thickness) have 4 hours fire resistance with a load-bearing wall having 2 hours resistance. Whilst a 215mm block both non-bearing and load-bearing walls have a 6 hour fire resistance.

Compared with Timber Frame and SIPS, it’s widely known that fire quickly consumes wood, even with the use of additional fire resisting materials; masonry’s resistance to fire is superior to Timber Frame and SIPS.

A timber frame build requires more safety features during development. Fires during construction have seen large timber frame projects burned to the ground in less then 9 minutes.

Accommodates Bespoke & Individual Design

Flexible During Design & Construction

Thin joint masonry is flexible at both design and construction stage, it accommodates bespoke and individual design. Features such as curved walls are easily accomplished, it also supports heavy loads with ease, such as pre cast concrete stair cases, concrete floors and steel work.

Changing details during the build stage and any mistakes on drawings such as dimension errors are quickly and easily overcome with thin joint, avoiding delays.

Thin joint blockwork accommodates any external Finishes you choose such as:

Brickwork Stone

Stone Waterproof Coloured Render

Waterproof Coloured Render

Sand and Cement Render Tile Hung

Tile Hung Timber & Wood Cladding

Timber & Wood Cladding

Book A Demonstration

If You’re also one of the many people wanting to take advantage of all the benefits building with Thin Joint Blockwork brings, You can see the system in action by requesting a demonstration.

Whether you’re a Housing Developer, Commercial Organisation or Planning to Build your Dream Home…

We’re happy to show you the way thin joint works by demonstrating the build method, including showing you samples of wall insulation, wall ties, bed joint reinforcement, movement ties, dpc, blocks and the thin joint mortar we use on a daily basis – allowing you to see all the benefits and quality first hand.

To book a demonstration: Simply contact us, via our web form email or phone, our company secretary will then take basic details from you, such as your name / organisation / company position, a brief description of the project you are planning, along with your contact telephone number.

After we have this information we will contact you within 72 hours to arrange a suitable time, date and location for a Thin Joint Blockwork demonstration.